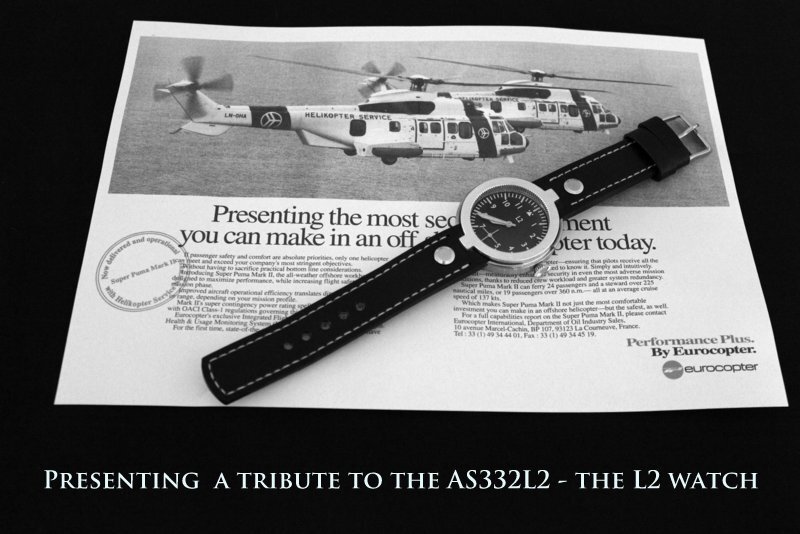

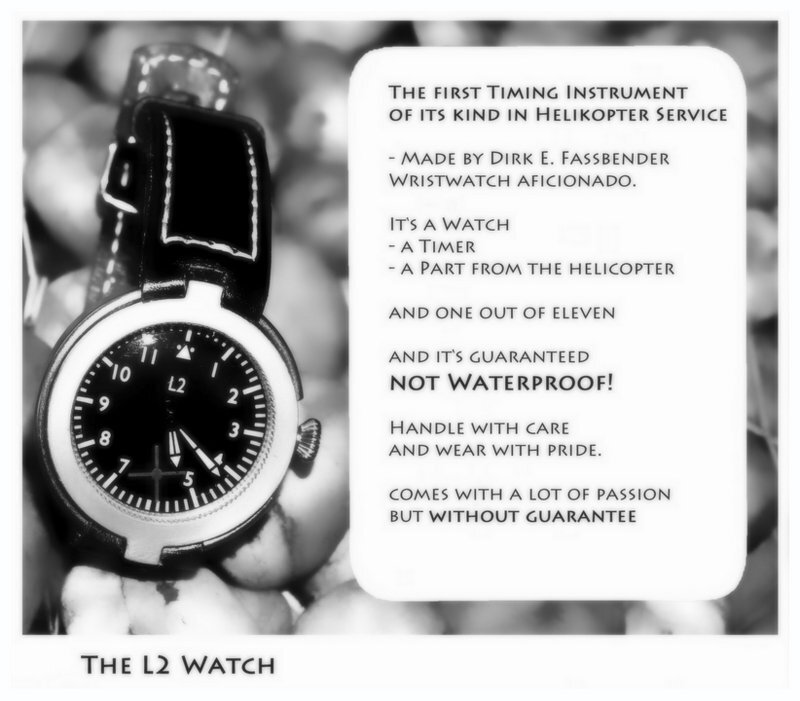

The "L2" watch by Dirk Ernst Fassbender

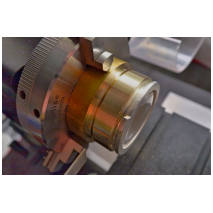

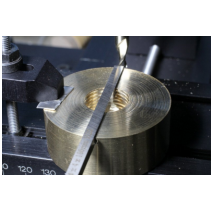

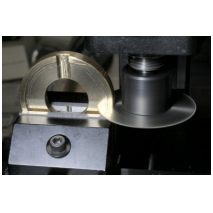

Mai 2013, what to do with a "one time use only" helicopter part? Well, let's make a wrist watch out of it. As it is a part, a safety lock washer, which needs to be changed on a regular basis and ends up as scrap, let's start this project. The part tends to collect some corrosion during the time of installment, but that can be removed easiliy. With some lathe work a 35 mm movement fits in perfectly and as there is a steel ring around the part the attachment of a strap to it was an easy decision. So 100% of the item can be used. Turning a groove inside on the lathe and a glass can be mounted. A little more thinking and work for a watch case bottom with glass needs to be done. As a prototype I will use brass.

July 2013, I'm waiting for a dial quotation as I want to have something unique to complete the watch. The case bottom will be made in steel, probably CNC made and ordered somewhere after a proper technical drawing is made. The brass bottom is now silver-plated an rhodium-plated.

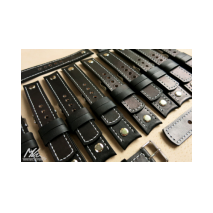

August 2013, the special made face is on order at Schätzle & Cie, Weil am Rhein, I found a company which will make the bottom part from stainless steal, I will order special made straps, as regular once are to short and the movements are ordered as well.

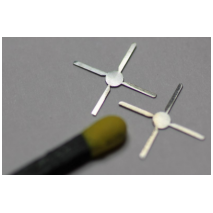

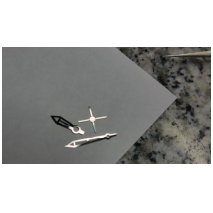

September 2013, working on the drawings for the second hand which will be a 4 blade main rotor imitation.

Oktober 2013, the faces are made, the second pointer is made and the final starp prototype is at work. Also I'm still looking for a way to add a number to the movement.

November 2013, still waiting for some parts to arrive before the 10 wachtes can be assambled. The second prototype starp is at work. Still try to find a way to number the watches properly.

November 2013, the missing parts are here, the straps are ordered, the laser engraving is in work, looking good.

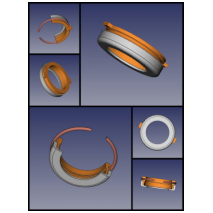

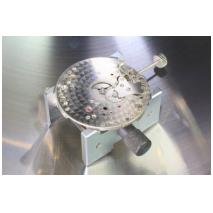

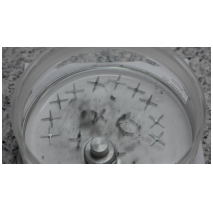

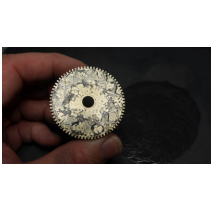

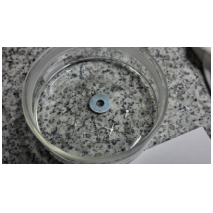

The part the watch is based on.

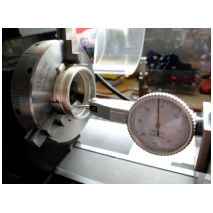

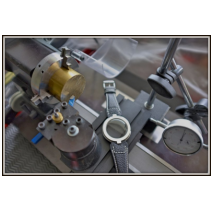

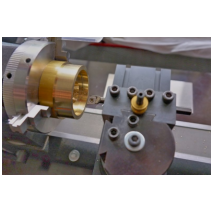

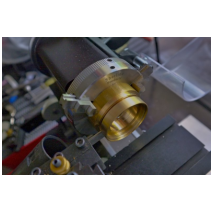

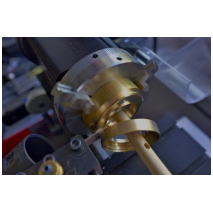

Building the L2 watch prototype.

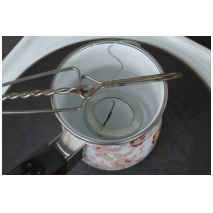

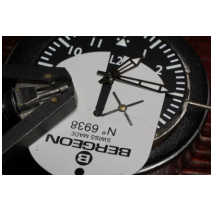

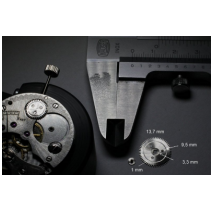

Parts made and bought for the L2 watch.

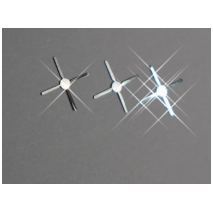

The L2 watch hands and the special made 4 blade main rotor.

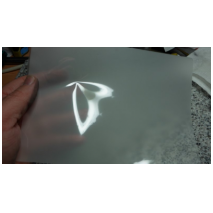

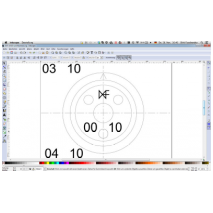

Logo and serial number

The hand made special L2 watch strap.

Special made L2 stem release case screw.

The L2 watch prototype on test tour down under.

2014-02-14, the second last auxiliary tools for the L2 watch, a movement fitting gauge, is finished.

The L2 watch zero version on assembly.

The L2 watch on video